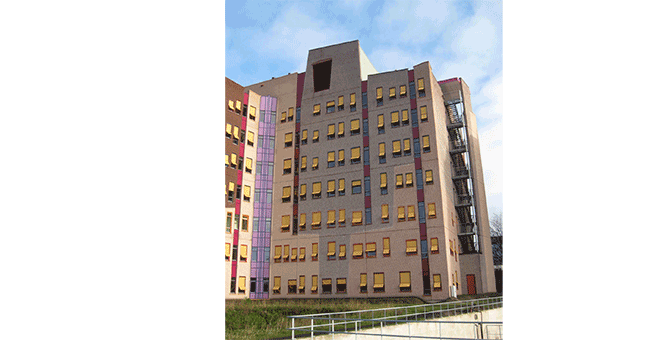

Good prospects: SELVE motors drive screens in Dutch hospital

Close collaboration with sun protection specialists ‘Schellekens & Schellekens’

Lüdenscheid | 20-10-2013

Schellekens & Schellekens’ develops customised solutions for large-scale projects of all kinds. The Dutch trendsetter for outdoor sun protection has been a SELVE specialist for seven years now and has been relying on convincing drive technology from Lüdenscheid ever since. SELVE motors have long since proven themselves in a wide variety of properties throughout the Netherlands: ‘The outstanding product quality was the deciding factor for us to work with SELVE,’ says Geert Kersten, Head of Purchasing and Products at Schellekens & Schellekens. Whether awnings, markisolettes, blinds or screens - all are operated with drive types ‘Made in Germany’. The Dutch company, which is part of the Hunter Douglas Group, produces a good five-digit number of units per year alone.

Close co-operation

All-rounder Schellekens & Schellekens designs, produces, installs and subsequently maintains special external sun protection solutions at its headquarters in Beuningen. This was also the case in Zwolle, where the screens of the new ISALA hospital were motorised with a total of 1800 SELVE-SP drives in three construction phases. For Schellekens & Schellekens, close, constructive co-operation with architects and planners is essential when planning sun shading systems of this size. The same applies above all to the company's suppliers and partners. In SELVE, they have found a competent full-service provider with high quality standards that stands for ‘reliability, flexibility and the rapid realisation of our wishes’, emphasises Geert Kersten. This was accompanied by good support and prompt and timely delivery from SELVE. According to Geert Kersten, this is essential for major projects such as the new clinic building.

However, the realisation of special requirements that Schellekens & Schellekens had with regard to tangible assembly simplifications was also of great importance. ‘For the hospital project, we used the classic drive, our tried-and-tested, durable and technically mature SP motor in series 2,’ explains Alexander Vogt, Assistant to the SELVE Management Board. The technical centrepiece of the universal drive is a spindle limit switch with microswitch and patented overwind protection. ‘The limit switch is set using two hexagon socket screws on the motor head,’ reports Alexander Vogt. Other advantages of the drive include a position-accurate cut-off - all these benefits were decisive for Schellekens & Schellekens.

Special wishes realised

In addition, in close coordination between the manufacturer from Lüdenscheid and the specialist customer from Beuningen, ‘special deposits were designed for the motor head so that it was exactly right for the head pieces used’, says Vogt: ‘In order to be able to assemble the screens more quickly and effectively, we at SELVE also developed special accessories and designed and built special tools’. The jointly generated added value then paid off directly on site: ‘This made assembly considerably easier for our employees,’ summarises Geert Kersten. SELVE has once again proven its expertise: ‘We have a suitable, flexible partner at our side for our special requirements, who offers us customised solutions and implements the corresponding new developments.’

The largest general hospital in the Netherlands, which has around 100 beds, was occupied in the summer. The sun protection system ‘works without any problems and the end customer is satisfied,’ says Kersten. This reference project will not be the last of this constructive, cross-border collaboration. It is documented by many other Schellekens & Schellekens projects in which SELVE drive and control technology - such as in the radio sector - is used.

Press contact

.png)

Press contact

Alexander Vogt

Head of Marketing

Telephone: 02351 925-108

A.Vogt@selve.de

Editor

Anja Pieper

Freelance journalist (DJV)

Phone: 0231/9767575

Anja-Pieper@t-online.de

About Selve

SELVE is a global market leader in the field of roller shutter belt winders and a sought-after specialist for drives and controls in the areas of roller shutters and textile sun protection. Based in Lüdenscheid, Sauerland, SELVE represents a high level of expertise in the development and production of roller shutter components as well as innovative drives and controls for sun protection as a medium-sized family-owned company. Founded over 150 years ago in 1866 at its current location, SELVE remains under the ownership of the founding family to this day.